Technology

Our machinery

Progressive and transfer presses

Stamping of metal pieces using transfer and progressive presses. Wide range of thicknesses and materials thanks to a fleet of presses ranging from 15 to 1,500 tonnes.

Machines designed by us with multiple slides and servomotors

Manufacture of shaped metal pieces with machines designed by us with multiple slides and servomotors. Thanks to the system we have developed, we are specialists in the manufacture of busbars with minimal material waste.

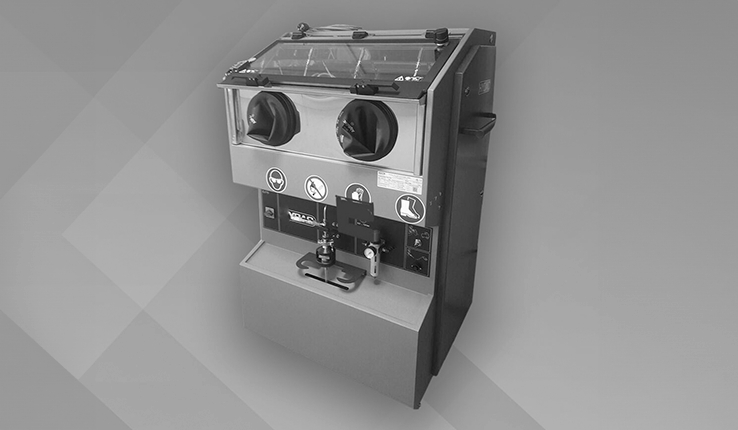

Specialised automatic machinery for assembly

Assembly of sets and subsets with specialised automatic machinery and manual processes. We integrate artificial vision, scanning and marking systems.

Plastic overmoulding in pre-stamped pieces

Plastic overmoulding in pre-stamped pieces for the manufacturing of connectors and similar pieces. The fleet of injection presses using reel feeders.

Continuous silver soldering for electrical contacts

For electrical contacts we carry out continuous soldered silver points inside the presses. Precision and productivity are achieved by carrying out the soldering as part of the stamping process.

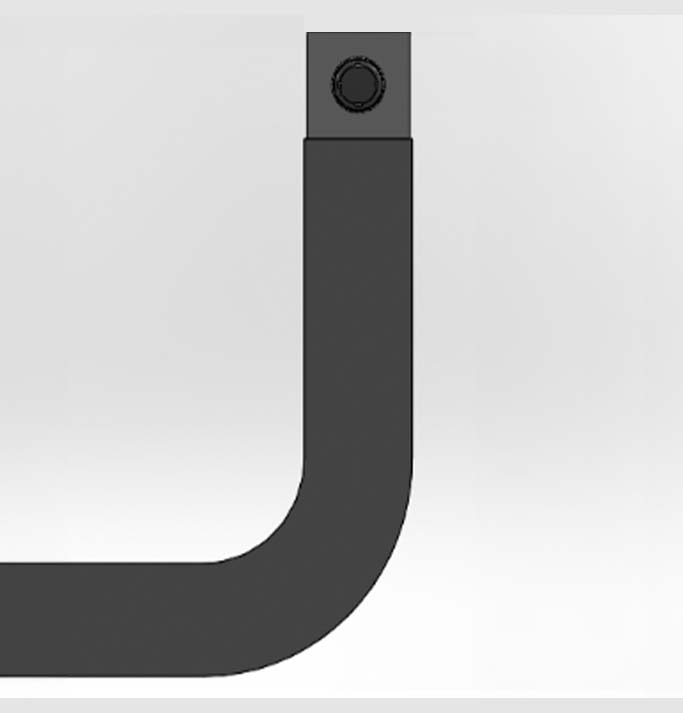

Manufacture of tubular rivets and the cutting and bending of tubes

Manufacture of tubular rivets, as well as the cutting and bending of tubes, with a fleet of lathes and specialised machinery.

Our Technology

Automatic traceability of laser marking

We have an innovative laser incorporated into the machine which allows us to automatically mark products providing distinct traceability for each piece.

Automatic Cleaning Line + Semi-automatic Assembly

We have an automatic cleaning line from the press and up to a clean room to ensure the cleaning requirements of the automotive sector (ISO 16232-10:2007-6, ZF 000 701 604, etc.).

Laboratory with special equipment

Coercimeter (automatic and quick measurement of the magnetic properties of the component).

Measurement of the thickness of the X-ray coating.

Particle-sized stereoscopic microscope equipment.

Automatic visual verification

Continuous electromechanical system to verify 100% of the pieces during production using cameras and AI.

01

Reduce the cost of busbars between 15-20% compared to conventional stamping.

02

Insulated raw material (PA, PI, or others)

03

Automatic insulation extraction mechanism at connection points.

Bending

tool

Conventional Stamping method

Scraps 91%

Proposed method stamping + Bending

Scraps 8%Materials

For metal stamping

Steel

Metal

Stainless steels

Stainless steels

Copper

Copper

Brass, bronze and non-ferric alloys

Brass, bronze and non-ferric alloys

Aluminium

Aluminium

Tin, nickel and silver

Tin, nickel and silver

Our machinery

Stamping

Stamping of metal pieces using transfer and progressive presses. Wide range of thicknesses and materials thanks to a fleet of presses ranging from 15 to 1,500 tonnes.

Forming

Manufacture of shaped metal pieces with machines designed by us with multiple slides and servomotors. Thanks to the system we have developed, we are specialists in the manufacture of busbars whilst ensuring minimal material waste.

Assembly

Assembly of sets and subsets with specialised automatic machinery and manual processes.

Plastic Injection

Plastic overmoulding in pre-stamped pieces for the manufacturing of connectors and similar pieces.

Silver soldering

For electrical contacts, we make continuous soldered silver points inside the presses.

Tubular rivets

Manufacture of tubular rivets as well as the cutting and bending of tubes.

R+D+I

Automatic busbar

production

- Reduce the cost of the busbars from between 15-20% compared to conventional stamping.

- Raw material with insulation (PA, PI or others).

- Insulation removal mechanism in connection areas.

Latest News